Looking for ATEX certified hearing aids?

Discover hearing aids with ATEX certification

Have hearing loss and work in a flammable or potentially explosive environment? Looking for hearing aids that not only keep you safe but offer durability and reliability?

There are ATEX-certification hearing aids on the market that offer reliable, robust, and safe hearing solutions.

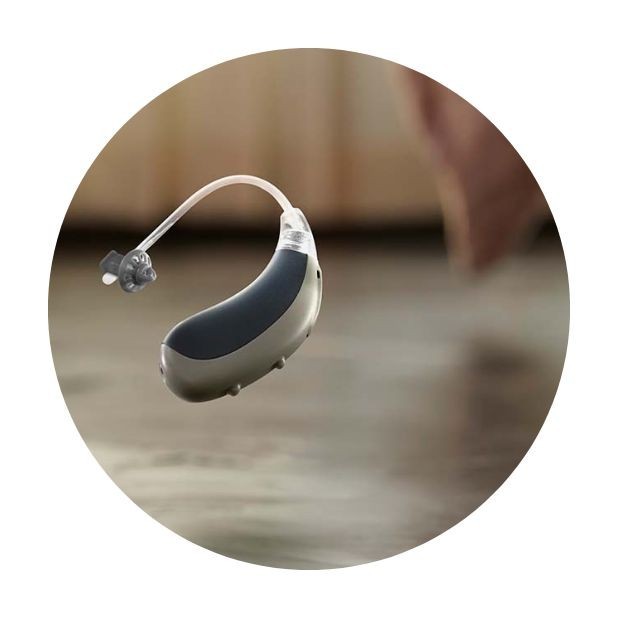

We briefly explore the Rexton Reach and BiCore hearing aid ranges, which both include ATEX-certified devices. Find out how these solutions will not only be safe to wear but also offer premium hearing support.

Below we also answer common questions such as: Are hearing aids intrinsically safe? Do hearing aids emit radiation? Do hearing aids produce EMF?

ATEX Hearing Aid Facts

David

Audiologist at Hearing Aid UK

0800 567 7621

ATEX Certified Hearing Aids

Safeguarding the hearing health of workers in hazardous environments

ATEX-certified hearing aids for explosive atmospheres

If you work in an environment where flammable gases, vapours, or combustible dusts are present - or if you're an employer responsible for workers in these conditions - you'll know that standard hearing aids simply aren't permitted.

ATEX-certified hearing aids are the only legally compliant solution that allows workers with hearing loss to perform their roles safely whilst meeting UK Health and Safety Executive (HSE) requirements.

What are ATEX hearing aids?

ATEX-certified hearing aids are specialised devices designed to meet stringent safety standards for wearing in potentially explosive atmospheres. For example, where flammable gases, vapours, or combustible dusts may be present. These environments could be industrial settings such as oil rigs, chemical plants, or mining locations.

The actual word, ATEX, comes from the French term "Atmosphères Explosibles", which outlines regulations for equipment intended for use in potentially dangerous working environments.

It doesn't stop at hearing aids either; other devices, such as mobiles, watches, and computers, have to be ATEX-certified to be used in these working conditions. For example, when looking at both Rexton Reach and BiCore hearing aid ranges,

"The ATEX group/class is printed on the ATEX card, which must be available at hand when the hearing aids are used in explosive atmospheres. Ask your hearing care professional for your ATEX card"

Rexton

Who needs ATEX hearing aids in the UK?

ATEX-certified hearing aids are essential for workers with hearing loss in industries including:

- Oil and gas extraction and refining - Both onshore and offshore platforms

- Chemical manufacturing and processing plants

- Pharmaceutical production facilities

- Mining operations - Particularly coal and mineral extraction

- Paint and solvent manufacturing

- Petrochemical facilities

- Grain handling and storage (flour mills, feed mills)

- Wastewater treatment plants

- Any environment classified as ATEX Zone 0, 1, 2, 20, 21, or 22

If you're unsure whether your workplace requires ATEX certification, your health and safety officer or facility manager will be able to confirm. Many companies conduct ATEX assessments that identify which zones require certified equipment.

ATEX certification testing and long-term durability

The certification process for ATEX hearing aids involves rigorous testing to ensure their reliability, durability, and safety in hazardous environments. These tests assess resistance to high temperatures, pressure, and impact, as well as their safety in explosive atmospheres.

This means that they are often made from robust housing materials that can withstand harsh conditions, offer protection from moisture and corrosion, whilst minimising the risk of leaks or electrical sparks.

ATEX Certification Hearing Aids

In addition to meeting safety requirements, what else can intrinsically safe hearing aids support you with?

Why standard hearing aids create explosion risks

Standard hearing aids contain electronic components that can generate tiny sparks or heat during normal operation - completely safe in everyday environments but potentially catastrophic in atmospheres containing flammable substances. Even a microscopic spark from a battery connection or circuit board could ignite gases or dust particles, causing an explosion.

ATEX-certified hearing aids are engineered to eliminate this risk through an intrinsically safe design. This means they're constructed in ways that make it physically impossible for them to release enough energy to cause ignition, even in the event of a malfunction.

ATEX hearing aids still prioritise features and comfort

ATEX-certified hearing aids are equipped with features that meet the needs of those with hearing loss who work in harsh environments. Features such as advanced Bluetooth, noise-cancelling, speech clarity and enhancement settings.

Thus ensuring that you can communicate effectively and hear through the noise of machinery and equipment, as well as being alerted to any safety notices, without sacrificing your safety.

Hearing aids with ATEX certification are also some of the most comfortable hearing solutions you can wear, as they often feature an ergonomic design for all-day comfort.

The reality of wearing hearing aids in industrial environments

Beyond explosion safety, ATEX hearing aids are built to withstand the physical demands of industrial work. They're designed to cope with:

- High noise levels - Advanced noise reduction helps you hear speech clearly even with heavy machinery operating nearby

- Extreme temperatures - Functional in both very cold offshore environments and hot industrial processing areas

- Moisture and humidity - Sealed against water ingress, steam, and condensation

- Dust and debris - Protected against fine particles that would damage standard hearing aids

- Physical knocks and impacts - Robust housing that survives the rough and tumble of manual work

- PPE compatibility - Designed to work alongside hard hats, safety goggles, respirators, and other protective equipment

For information on ATEX hearing aids and employer responsibilities

Under the Equality Act 2010, employers have a duty to make reasonable adjustments for employees with disabilities, including hearing loss. In ATEX environments, providing certified hearing aids that allow a worker to perform their role safely could constitute a reasonable adjustment.

Additionally, under Health and Safety at Work regulations, employers must ensure workers can hear safety warnings and communicate effectively in hazardous environments. For workers with hearing loss, this often means that providing ATEX hearing aids is not just beneficial but legally necessary.

If you're an employer investigating ATEX hearing aids for your workforce, we can provide consultations that address both the audiological needs of your employees and the compliance requirements of your facility. We work with occupational health teams across the UK to ensure workers get appropriate hearing solutions that meet both safety and regulatory standards.

Understanding ATEX markings on your hearing aids

Your ATEX hearing aids will come with certification documentation that specifies which zones they're approved for. This typically appears as:

- Equipment Group II (for surface/non-mining use) or Group I (for mining)

- Category rating (1, 2, or 3)

- Zone compatibility (which zones you can safely wear them in)

For example, you might see: II 2G Ex ib IIC T4 Gb - This indicates equipment suitable for Zone 1 gas atmospheres. Your audiologist will provide you with an ATEX card that must be carried whenever you're wearing the hearing aids in hazardous areas. Your employer's health and safety team may also need to see this documentation for their records.

Definition of ATEX zones table

In brief, ATEX zones are locations where there is a risk of explosion or combustion. For example, combustion dust will eventually build up over time and emit flammable gases. This also determines how equipment in hazardous working environments is labelled and used, and potentially how long a worker can be in that atmosphere.

Below, we highlight each ATEX zone, its definition, and the level of explosive atmosphere present.

| ATEX Zone for Gases | ATEX Zone for Dusts | Definition | Explosive Atmosphere Present |

| 20 | 0 | Air and flammable substances such as vapour, gas, and mist. | Frequent, continuous, long periods. |

| 21 | 1 | Air and flammable substances such as vapour, gas, and mist. | Likely to occur, occasionally. |

| 22 | 2 | Air and flammable substances such as vapour, gas, and mist. | Not likely to occur in short periods. |

Rexton ATEX Hearing Aids

Are hearing aids intrinsically safe? Do hearing aids emit radiation? Hearing aids emit very low radiation, and we believe it is not enough to cause health risks. Most hearing aids now use Bluetooth LE (low-energy,) which is safer than your headphones or car's wireless connection.

There are only a select few hearing aids that are ATEX-certified, which offer this security. Rexton BiCore and Reach hearing aid ranges are ATEX certified - prioritising both safety, performance, and overall enhancing the well-being and productivity of workers in challenging industrial environments.

"We have ATEX Certification on Rexton Reach and BiCore products. ATEX certification verifies our hearing aids are both tested and approved to be classified as intrinsically safe.

This is crucial for individuals in certain fields of work where use of hearing aids are only allowed if there is ATEX certification"

Rez Moghimi - Rexton UK Representative

Rexton Reach ATEX Hearing Aid Highlights

Multi-Voice Focus: Enables you to hear multiple voices all at the same time - even in background noise with Multi-Voice Focus technology.

This is made possible by scanning your surrounding environment 1,000 times a second using 4 focus beams and adapting to switches in speaker positions and volumes automatically.

Seamless connectivity: Includes MFi and ASHA protocols that connect seamlessly to mobiles. It’s also future-proof, requiring only a quick firmware update to connect via Bluetooth LE audio.

Rechargeable technology: Offers sustainability and peace of mind that you will have enough power to get you through the day. Battery life is 18 hours on a full charge (5 hours streaming).

Lifeproof: They are built using rugged components and have been rigorously tested to ensure they can withstand everyday challenges and harsh environments with ATEX certification.

Models available: Rexton Reach R-Li, Rexton Reach R-Li T-coil, and Reach SR RIC models.

Explore the Rexton Reach hearing aid range here

Rexton BiCore ATEX Hearing Aid Highlights

BiCore Technology: Ensures you can hear speech sounds easily from a work colleague or friend, whilst you remain aware of background noise in your environment. This could be safety alerts, machinery, a phone ringing, or equipment.

Soundpro 2.0: Harnessing an innovative blend of inputs, including real-time motion data and sophisticated sound directionality. It continually fine-tunes sound settings to mirror your environment seamlessly and automatically.

Connectivity: They incorporate cutting-edge rechargeability technology, featuring various connectivity options such as Made-for-iPhone compatibility, direct Bluetooth streaming to ASHA-enabled Android phones, and a suite of wireless accessories.

Models available: Options include slim RIC models, traditional BTE models, and compact custom models, such as BiCore R-Li and R-Li T and BiCore B-Li Rugged.

Explore the Rexton BiCore hearing aid range here

Getting ATEX hearing aids through Hearing Aid UK

We work with audiologists across the UK who have experience fitting ATEX-certified hearing aids for industrial workers. The process typically involves:

1. Initial consultation and hearing assessment - We establish your hearing needs and confirm your workplace's ATEX zone classifications.

2. Employer liaison - If your employer is funding or subsidising the hearing aids, we can work directly with your occupational health or HR department.

3. Selection and ordering - We'll recommend the appropriate ATEX-certified model for your hearing loss and work environment.

4. Fitting and programming - Your hearing aids are precisely fitted and programmed, with workplace communication needs prioritised.

5. ATEX documentation - You'll receive all necessary certification documentation and your ATEX card for carrying on site.

6. Workplace trial period - A follow-up appointment after you've worn them in your actual work environment to make any necessary adjustments.

7. Ongoing support - Regular servicing, adjustments, and replacement parts as needed throughout the life of the devices.

To arrange a consultation about ATEX hearing aids, call us free on 0800 567 7621. We can discuss your specific workplace requirements and help you understand whether employer funding might be available.

What are the other benefits of Rexton ATEX-certified hearing aids?

Impact resistant: Tested to ensure they can handle impact.

Chemical resistant: Tested to ensure creams and oils will not cause damage.

Sweat resistant: Tested to ensure they can handle sweat.

Heat resistant: Tested to check that they are built for high temperatures.

Vibration resistant: Tested to ensure they perform with vigorous movement.

UV resistant: Tested to ensure they can endure UV exposure.

How tough are Rexton Hearing aids? Watch the video below

What's included in our hearing aid prices?

Our specialist service includes:

Do not spend hundreds of pounds without getting a second opinion from us.

Please call us on 0800 567 7621

Not only are the prices great, but the service is fantastic! Many thanks to your team.

Not only are the prices great, but the service is fantastic! Many thanks to your team.Other pages you might find useful

Ask the Experts

6 Morton Lane

Walkwood

Redditch

Worcestershire

B97 5QA

Latest Launch

When we refer to a product as 'Latest Launch', we mean it is the latest to be released on the market.

New

When we refer to a product as 'New', we mean that the product is the newest hearing aid model on the market.

When we refer to a product as 'Superseded', we mean that there is a newer range available which replaces and improves on this product.

Older Model

When we refer to a product as an 'Older Model', we mean that it is has been superseded by at least two more recent hearing aid ranges.